Mobile concrete batching plant south africa has capacities of 25m3, 35m3, 50m3, 60m3 and 75m3. Models include YHZS25, YHZS35, YHZS50, YHZS60 and YHZS75. The voltage is 220V, and the contacts can be customized. We can offer both SABS and ISO9001 certificates.

Main parts of mobile batching plant south africa

1. Chassis: It is a cantilever chassis of mixing main machine, including the traction pin and parking outriggers of the towing truck. The chassis carries the concrete mixer and measurement units for cement and water admixture, with the patrol walking platform and handrail attached around.

2. The control room: located at the bottom of the chassis of the main machine and is equipped with the full-automatic control system of the mixing station. The control system is the same as that of a stationary ready mix concrete plant. The control rooms serves as the front support of the whole plant in plant operation while retracted into the structure inter space in travelling state, when all wires keep connected well.

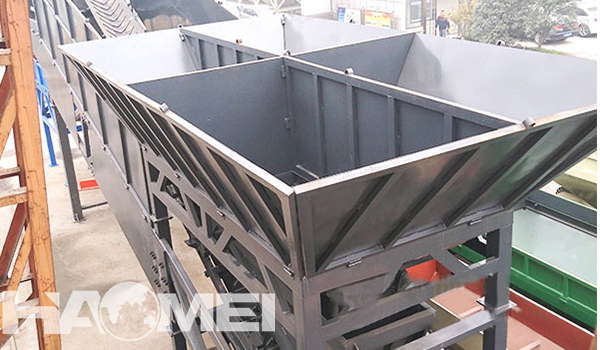

3. Aggregate batching and metering part: located at the rear end of the whole plant, and the upper part is aggregate (sand, stone) storage hopper, which can be divided into 2 or 4 grids, and is equipped with a heightening plate to increase the storage capacity. The doors of each grid opens in turn pneumatically and follow a multiple material cumulative metering method for aggregates. The bottom of the whole part is equipped with a walking rear bridge and a frame leg for working.

4. Belt conveying frame: the frame is a truss structure connecting the chassis of the main machine and the aggregate batching frame, and is equipped with a belt frame. The main structure of the mobile concrete batching plant south africa is composed of the main frame, the belt frame and the batching frame.

5. Peripheral parts: including cement bins and screw conveyors, kept together either in traveling or working state of the plant. This helps save time in site transfer and preparation work before the plant comes into work.

6. Concrete mixing machine: JS type forced mixer is generally used, which can quickly and evenly mix either fluid or dry hard concrete.

Price

We make South Africa, Kenya and other African countries as our main markets. Units and machines are customized to match local needs. Email april@concretebatchplant24.com for a price!