A concrete mixer pump is formed by combining a concrete trailer pump and a concrete mixer. The adding of a automobile chassis further makes it a portable concrete mixer with pump. The same type of mixer pump falls on varied names, like a concrete mixer and pump combination, a portable concrete mixer and pump, a concrete mixer with pump, a mobile concrete mixer with pump etc. All of these are featured by three functions: concrete mixing, concrete pumping and high mobility.

Advantages over A Concrete Pump Truck

1. Equipped with both diesel and electric drive forms, it can be used for both diesel power construction and electric power construction, so there are fewer limitations in use.

2. The operation is simple, fast and safe even at night. In the almost fully mechanized operation mode, labor work is only needed in pipeline laying, cement feeding to the forklift and concrete smoothing after pumping. In this way, construction in rural areas, township civil construction, factory building construction, small commodity building construction, villa group construction, residential building construction, field construction and other fields will progress very quickly.

3. Lower price.

Parameters for Diesel Concrete Mixer with Pump 30m3

Maximum pumping volume: 30m3

Pumping pressure: 8-10Mpa

Pumping power: 52kw

Maximum mixing volume: 20m3

Max. Aggregate size: 40mm(pebble)/30mm(broken stone)

Conveying tank diameter: 200-230mm

Size(L*W*H): 5100*2200*3150

Weight: 5300kg

concrete mixer and pump combination

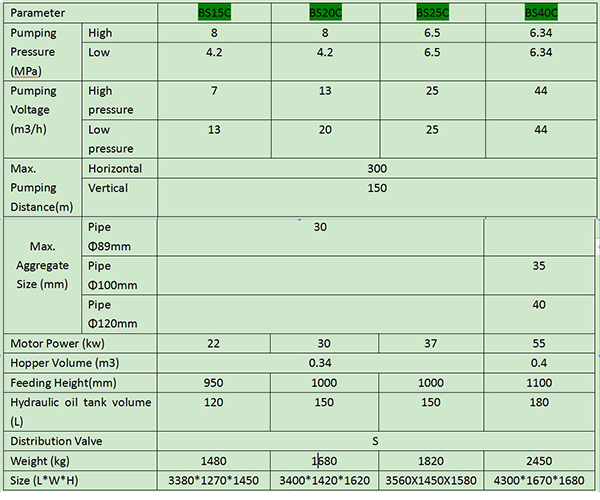

Technical Parameters for Electric Concrete Mixer Pump

Features

1. Long transmission distance and high pumping floor

The concrete mixer with pump can transport vertical 50 meters (15-20 floors) to meet the higher demand of self-built houses. The horizontal distance is 150 meters to meet the demand of rural road hardening.

2. High production efficiency and simple operation

The concrete mixer and pump can mix and transport 30 cubic meters of concrete every hour, the efficiency is about 3 times higher than that of traditional equipment, and it is fully automatic control, which can be operated by one person and saves labor. The actual income will also be about three times that of traditional equipment.

3. Construction is safer and the risk factor is low

Pipeline transportation is used to reduce the risk factor during the construction process. No stones will fall on employees and passers-by, and there will be no wire rope breakage and injury to workers.

Application Scope

The BS15-20 model is a fine stone concrete conveying equipment specially developed for the characteristics of floor heating construction. It is suitable for large area and high efficiency construction of fine stone concrete filling layer or mortar filling layer in floor heating engineering, and can also be used in construction engineering. , Fine stone concrete or mortar transportation in tunnels, mines and other projects.

BS15-20 model can be used as a spray pump after it is equipped with spray accessories, which is used for spraying and sprinkling of concrete, mortar, refractory materials and green soil.

The BS40C model is a concrete pump for engineering construction, which can be used for concrete construction of high-rise buildings, railways and highway tunnels, bridges and culverts, hydropower, mining and national defense projects.