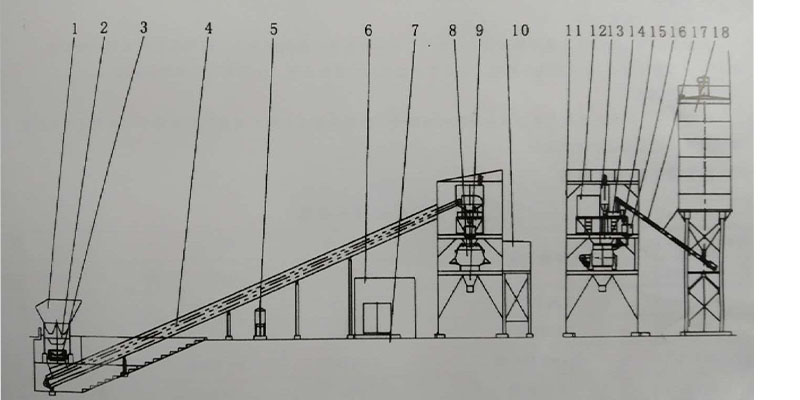

The general structure of a concrete batching and mixing plant is as shown in the picture below. A plant consists of material storage system, weighing system, control system, conveying system, liquid supplying system, pneumatic system, mixing system, main frame, control room and dust removing system. These parts realize the storage, measuring, conveying, mixing and discharging of concrete raw materials.

1. Material Storage System

The storage system of a concrete batching plant include two parts: raw material storage part (powder tanks, water tanks, aggregate storage hoppers and additive tanks) and concrete flow part (discharge hopper).

2. Weighing System

The weighting system is composed of weighing parts for aggregates, powders (cement, powder mixture), water and liquid additives.

3. Conveying System

The conveying system mainly functions to convey aggregates and powders.

4. Liquid Supplying System

Liquid supplying system consists of parts for water supply and additive supply.

5. Pneumatic System

The pneumatic system mainly includes an air compressor, pneumatic FRL, gas tanks, packaging valves, filtration pressure reducing valves, air cushions, pneumatic butterfly valves, air cylinders and air pipes.

6. Mixing System

Our concrete mixers are composed of gearing devices, axle end sealing parts, cylinders, lubricating devices, the top cover, the water distributing device, the discharge system and the mixing device.

7. Main Frame

The main frame is made of steel, composed of the top, the staircase, the fence, the weighing floor, the mixing floor and the supporting legs from the upper to the ground.

8. Control Room and Control System

The control room is for operation and management of a concrete batching plant. It’s the brain deciding movement of each part of the plant, consisting of the air-conditioning system, the power cabinet, furniture, a computer, PLC and cable wires.

9. Dust Removing System

The dust removing system is responsible for three parts of dust removing: weighing and discharging of cement and admixture, cement tank feeding by a cement delivery vehicle and aggregate feeding by the belt conveyor into waiting hoppers.